Overview

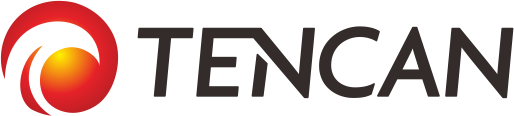

Lab jar mill is a kind of equipment used for ultra-fine grinding and

mixing for laboratory and small batch production, which is also called

rolling mill with more than two working positions. The machine is

preferred equipment for scientific research, education, experiment and

production due to its advantage such as elegant and fashion design,

compact structure, easy operation, high efficiency, and uniform

granularity. It is widely applied to industries of electronic materials,

magnetic materials, biological medicine, ceramic glaze, mental powder,

nonmetallic minerals, new materials and etc. Optimal design of rotating

speed is adopted in the machine. Mill jar is dragged to rotate by rubber

roller and balls inside the jar make incline flow movement and disperse

materials. Thus it obtains best effects of grinding. As a result,

materials are ground to micro powder. Timing control panel is adopted in

the machine with controlling functions of pausing and cumulative

timing, so that you may set working time according to requirement at any

time. It not only saves time and labor, but is easy for operation.

Working Principle

When the machine works, the grinding media and the materials of the

cylinder are rotated to a certain height. Due to the gravity, they fall

down from the tube wall. The materials are crushed by impact action of

the grinding media, and friction and shearing action of grinding media’s

rolling and sliding. It not only saves time and labor, but is easy for

operation.

Features

1. More kinds of sample material can be ground each time.

2. It can be operated intermittently or continuously.

3. Timing can be set as per users’ needs.

4. Suitable for ultrafine grinding with high efficiency of pulverizing.

5. Rubber roller is made of special materials and durable in use.

Application Cases of Planetary Ball Mill

Application Cases of Planetary Ball Mill

Technical Parameters of Lab Jar Mill

Category | Model No. | Power Supply | Rotate Speed | Max Load Per Jar | Dimensions & Net Weight |

2 Work Positions | GQM-2-5 | 220V-50Hz or 60Hz/0.75kw | 50-410 rpm | 35KGS | 950*480*685mm 59KGS |

GQM-2-15 | 220V-50Hz or 60Hz/1.1kw | 40-365 rpm | 80KGS | 1130*550*690mm 80KGS | |

GQM-2-20 | 220V-50Hz or 60Hz/1.5kw | 40-340 rpm | 120KGS | 1350*650*690mm 92KGS | |

4 Work Positions | GQM-4-5 Single layer | 220V-50Hz or 60Hz/0.75kw | 50-410 rpm | 35KGS | 950*660*690mm 70KGS |

GQM-4-5 Double layer | 220V-50Hz or 60Hz/0.75kw | 50-410 rpm | 35KGS | 950*480*870mm 92KGS | |

GQM-4-15 | 220V-50Hz or 60Hz/1.5kw | 40-365 rpm | 80KGS | 1130*800*690mm 95KGS | |

GQM-4-20 | 380V-50Hz or 60Hz/2.2kw | 40-340 rpm | 120KGS | 1350*820*690mm 122KGS | |

8 Work Positions | GQM-8-5 | 220V-50Hz or 60Hz/1.5kw | 50-410 rpm | 35KGS | 950*660*960mm 106KGS |

GQM-8-15 | 380V-50Hz or 60Hz/2.2kw | 40-365 rpm | 80KGS | 1130*800*960mm 152KGS |

Remarks:

1. Customized model in different sizes is acceptable.

2. Customized model with safety cover is available.

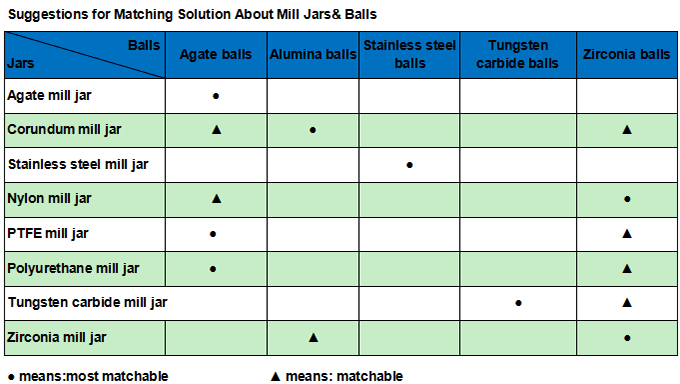

Matching Solutions Recommendation for Materials & Mill Balls roll mill jars,like stainless steel mill pot, zirconia mill pot, alumina mill pot, nylon mill pot, PU mill pot, tungsten mill pot, hard metal mill pot and tempered nylon mill pot etc. Further, we also provide stainless steel mill balls, zirconia mill balls, alumina mill balls, PU mill balls, steel carbon mill balls,tungsten mill balls, etc.

Available Roll Mill Jars & Specifications

Description of Roll Mill Jars | Available Specifications |

Normal ceramic roll mill jar | From 1.0L to 15L |

304 Stainless steel roll mill jar | From 0.5L to 20L |

Alumina ceramic (Corundum) roll mill jar | From 0.5L to 10L |

Nylon roll mill jar | From 0.5L to 20L |

Polyurethane roll mill jar | From 0.5L to 20L |

PTFE/Teflon roll mill jar | From 0.5L to 20L |

Tungsten carbide roll mill jar | From 250ml to 3L |

Roll jacket (Stainless steel) | 0.5L to 3L |

316l Stainless steel roll mill jar | Customized |

Matching Solutions Recommendation for Materials & Roll Mill Jars

Materials & Requests | Recommended Solutions |

Soil materials and other materials which are not allowed with any impurity contamination | Agate mill jar |

Metal or nonmetal which are not allowed with any impurity contamination | Zirconium mill jar |

High hardness materials like diamond, tungsten carbide | Tungsten carbide mill jar |

Strong add & alkali materials, or other materials under high temperature | PTFE mill jar |

Iron ore materials or other materials with low impurity sensitivity | 304 stainless steel mill jar |

Pigment or materials with later processing under high temperature | Nylon mill jar |

Aluminum materials like ceramic glaze | Corundum mill jar |

Electronic materials like lithium battery | Polyurethane mill jar |

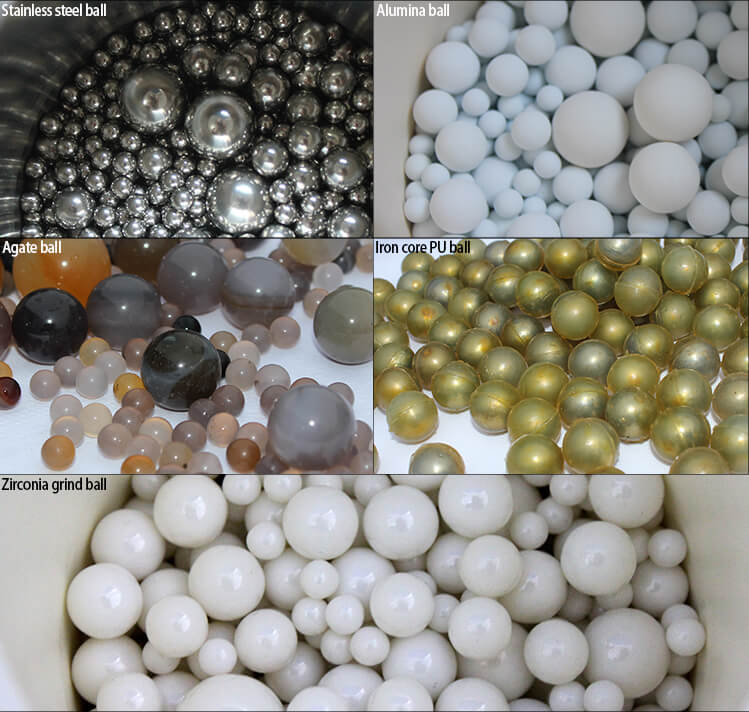

We can also provide all kinds of mill balls like stainless steel balls, zirconia balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, hard metal balls, silicon nitride balls, high wear resistant steel ball, manganese steel balls, nylon balls, cemented carbide, crystal glass and other special metal materials.

Available Mill Balls & Specifications

Descriptions | Available Specifications (Diameter Size) |

304 Stainless steel mill balls | From 1mm to 30mm |

316l Stainless steel mill balls | From 1mm to 30mm |

Alumina mill balls | From 1mm-50mm |

Zirconium mill balls | From 0.1mm to 30mm |

Agate mill balls | From 1mm-30mm |

Tungsten carbide mill balls | From 2mm to 20mm |

Carbon steel mill balls | From 1mm to 30mm |

Iron core PU mill balls | From 15mm-30mm |

Matching Solutions Recommendation for Materials & Mill Balls

Grinding Balls | Hardness ( Mohs ) | Characteristics |

Tungsten Carbide Balls | ≥9.0 | Super wear-resistance, no impurity, anti-corrosion, High temperature resistance |

Zirconia Balls | ≥9.0 | Super wear-resistance, no impurity, anti-corrosion, High temperature resistance, commonly used for medicine, food and other materials which can not be allowed with impurity. |

Stainless Steel Balls | ≥6.0 | Wear-resistance, anti-corrosion, high temperature resistance, brings some impurity. |

Agate Balls | ≥7.0 | Super wear-resistance, commonly used for medicine, food and other materials which can not be allowed with impurity, anti-corrosion, high temperature resistance |

Alumina Balls | ≥8.5 | Wear-resistance, anti-corrosion, high temperature resistance, brings impurity |